J&C Aero, an international aviation design and production company, has announced investing up to €1.5 million into the acquisition and integration of new innovative equipment into its cabin interior production processes.

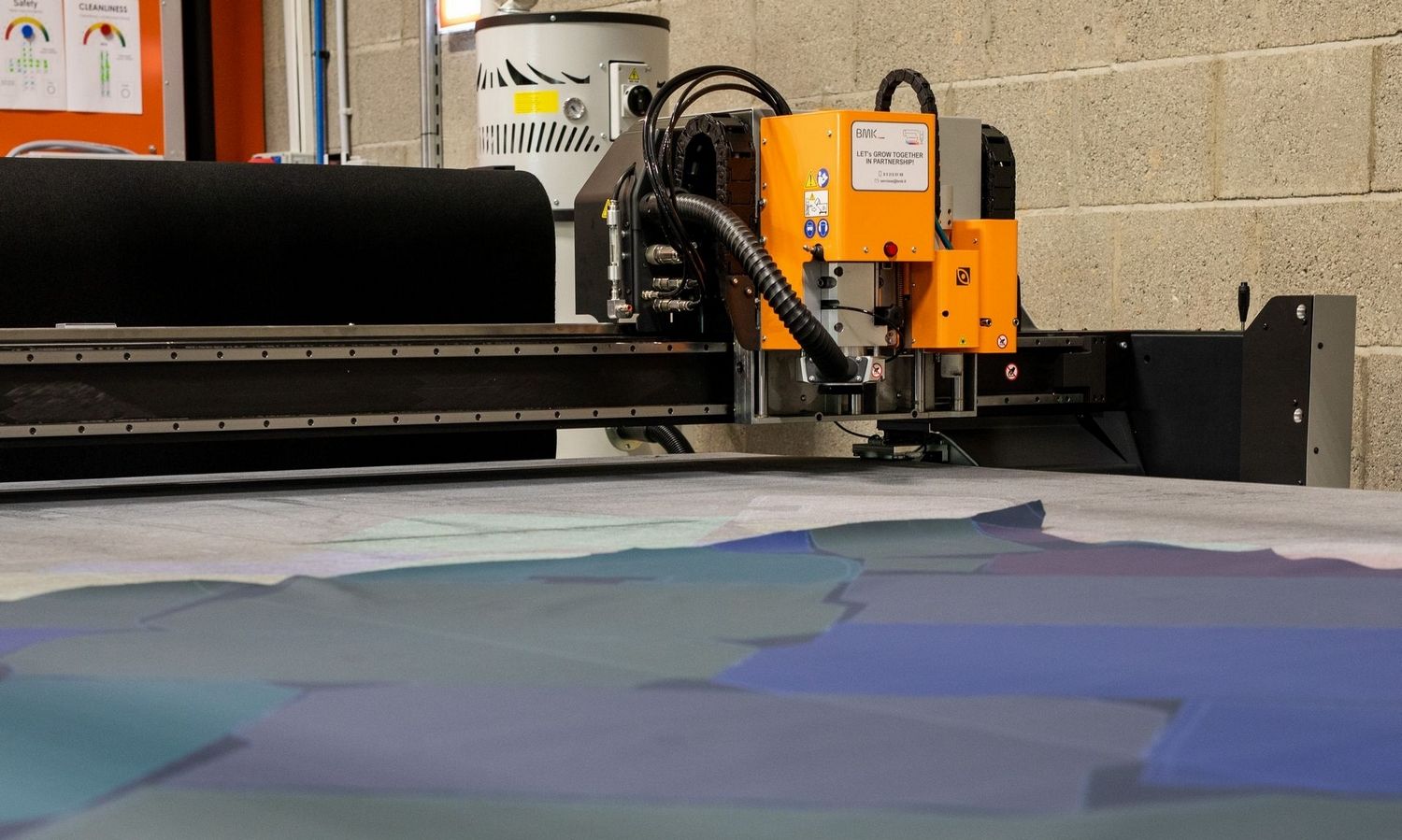

The modernization program is aimed at further automation and robotization of J&C Aero’s certified in-house production processes. Amongst other, the company plans or has already acquired a super-speed CNC vertical mill for a three-fold increase in metal items production, a digital cutting system to significantly shorten the duration and improve the precision of fabric and leather cutting, a programmable electronic pattern sewing machine to use enhanced-quality seams, a full-fledge foam moulding line for automated production of whole cushions, as well as a high-performance spray booth to streamline the painting process.

In addition to the automatization of production processes, the new equipment will also enable J&C Aero to significantly lower its environmental impact thanks to a decreased amount of waste materials, product defects, as well as raw materials and energy used during production.

“The pandemic and the war brought a handful of challenges to the aviation market. The past few years empathized (yet again) that the cost of being inefficient can be dreadful, both for large and small businesses,” says Vitalijus Malyška, COO at J&C Aero. “We have been upgrading our infrastructure for several years, and with a new HQ and production facilities just around the corner, it’s time for a new step towards Industry 4.0. The new equipment will enable us to be more precise, more productive, and more agile while also becoming more sustainable as a business.”

According to Mr. Malyška, the automatization and digitalization program will significantly improve the production and maintenance of laminated seat covers, moveable class dividers, windscreens and partitions, and a variety of other cabin interior elements.